3. Outdoor installation – Damp and wet areas and rooms

3.1 Basics

In general when selecting components, the manufacturer‘s instructions as to the product properties simply act as a guide for the user. These properties should always be viewed in the context of the relevant installation requirements such as the installation regulations according to DIN VDE 0100-ff.

Depending on the local circumstances, additional protective measures may have to be fulfilled by the user. The individual factors are described in greater detail below.

3.2 Protection against UV radiation

UV radiation can cause severe structural damage or even destruction in a wide variety of plastics. Products made from the material polystyrene (PS) must therefore not be used outdoors. Spelsberg developed the IQ series products for this scenario. A material is used for these products that has a high resistance to UV radiation. In a weathering test according to DIN 53 387 (replaced by DIN EN ISO 4892-2), this material produced optimum results in a 1000-hour test. This material also passed a weathering test according to UL 746 C, without any limitations.

3.3 Protection against high temperatures

Installed electrical appliances generate power loss during operation. The enclosures manufactured by Spelsberg are tested during the approval test for the maximum power loss in the enclosure. Detailed tables on this topic are provided in the catalogue, taking account of the ambient temperature and the installation type. Switchgear assemblies are designed for ambient temperatures of between -25.°C and +35.°C (24-hour average). A temporary increase in temperature to 40°C is not a problem.

Even if, for example, iQ products from Spelsberg are suitable for temperatures of between -40°C and +80°C, the manufacturer‘s instructions and the requirements of the relevant product safety standards must be checked for installed devices such as line protection, fault-current circuit breakers or fuses when designing the housing.

Solar radiation or other heat sources can cause additional increases in the internal temperature which are not permitted and must therefore be avoided. Reliable operation of electrical

equipment no longer be guaranteed under certain circumstances. DIN VDE 0100-520 (VDE 0100-520): 522.1.2 Cable and conductor systems including accessories may only be installed or moved under ambient temperatures which are within the limit values specified by the manufacturer or in the relevant product standard.

3.4 Protection against chemical influences

For installations in areas with increased levels of hazardous substances in the environment, the suitability may be correspondingly reduced. Information is available in the table „Material characteristics“.

iQ products are resistant to mineral oil, vegetable fats and animal fats.

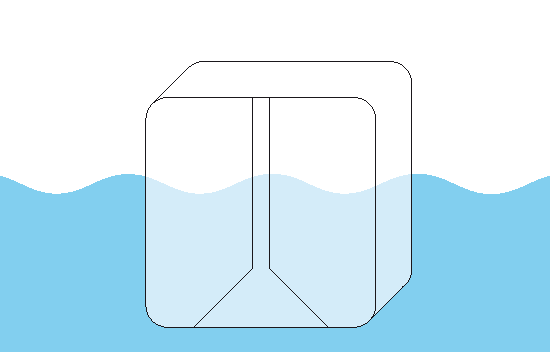

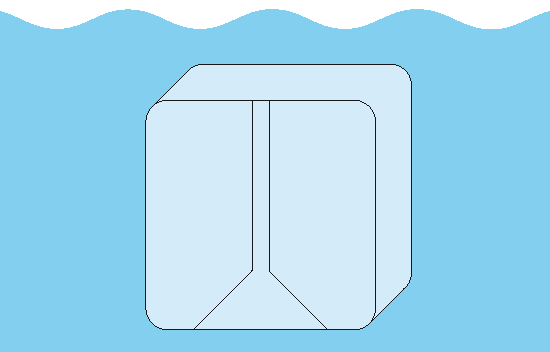

3.5 Protection against condensation

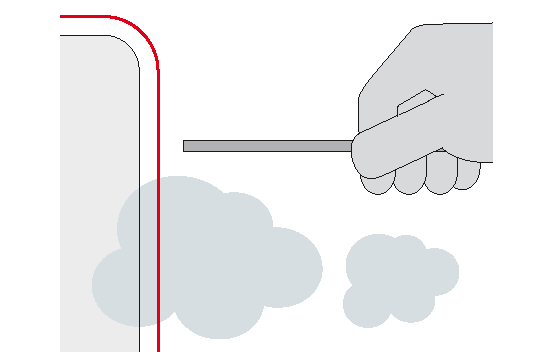

The more tightly sealed the equipment, for example junction boxes or distributor housings, the greater the likelihood of condensation forming. This is especially the case at locations where highly fluctuating temperatures are to be expected.

These effects are intensified by the power loss generated in the enclosures. Owing to the differences in temperature, a difference also arises in the pressure conditions, which causes the enclosure to draw in air when the temperature changes. The next time the temperature increases, the humidity in this air condenses on the cold surface of the housing, for example on the lid. This process is only reversible to a limited extent, so the water collects in the housing. Since this effect occurs regularly, even daily to an extent, a considerable volume of water may collect internally. If this housing has an increased protection rating, it no longer discharges this water with the result that its seal actually has a negative impact. Damage will result.

Under DIN VDE 0100-520, precautions must be taken with respect to drainage of water if water collects or condensation can occur within cable and conductor systems.

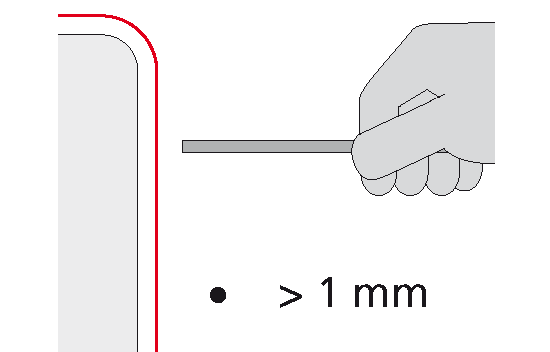

Spelsberg junction boxes in the various product groups have break-out condensation openings on the rear housing or mounting surfaces. These should be opened in such a way that when installed they are on the underside of the housing so that any condensation can drain off.

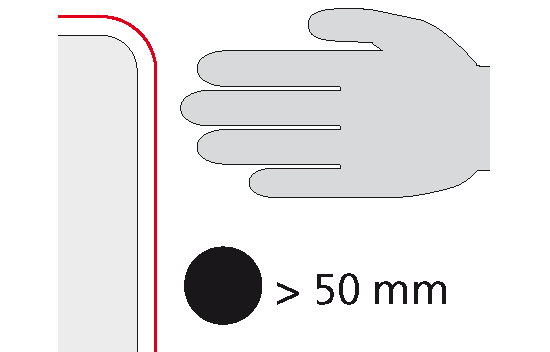

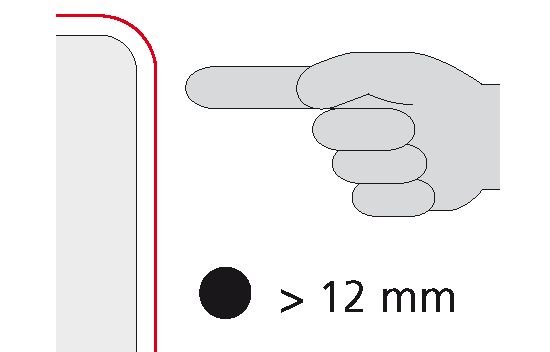

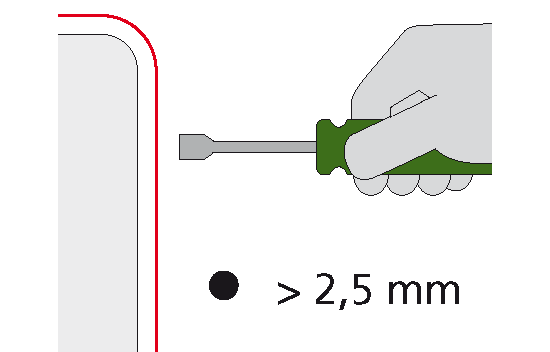

This only applies under the condition that no increased demands are imposed with respect to protection against accidental contact or foreign bodies (> IP2X or dust protection).

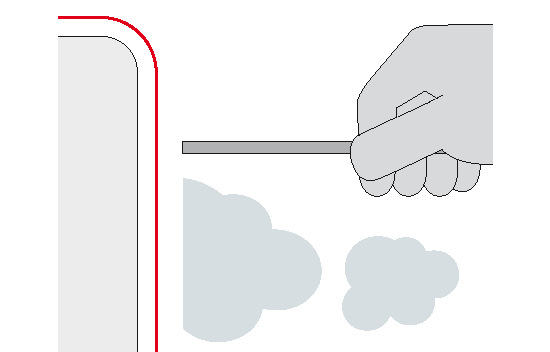

If requirements for contact protection or foreign body protection are also imposed on the housing, for example IP3X, we recommend use of els ventilation seals. These seals come in the size M20, are fitted in the corresponding cable inlet openings on the underside and the side surfaces and offer splash water protection up to IPX4 when properly installed. We recommend an installation that offers a so-called chimney effect.

A pressure compensation element (IP68) is also available for higher protection ratings.

- In this context, the only els product that can fully exclude the possibility of condensation forming is the Abox XT, as no air is available in this enclosure owing to the cast resin filling.

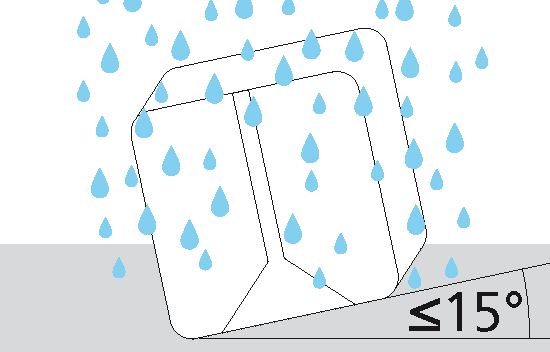

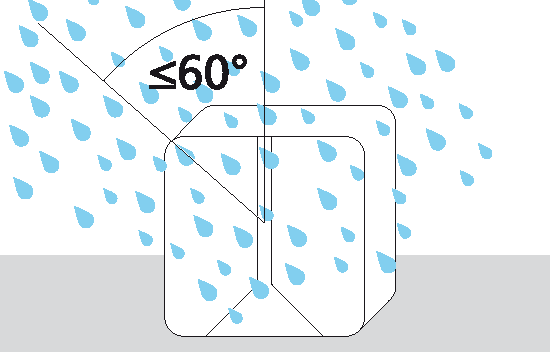

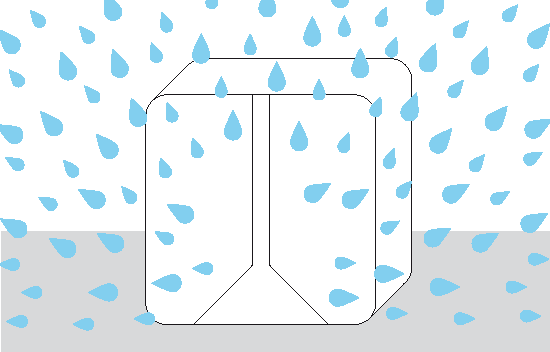

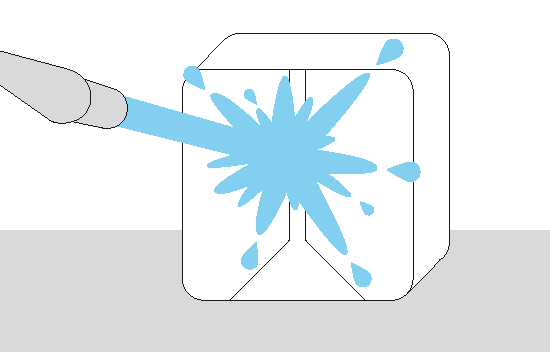

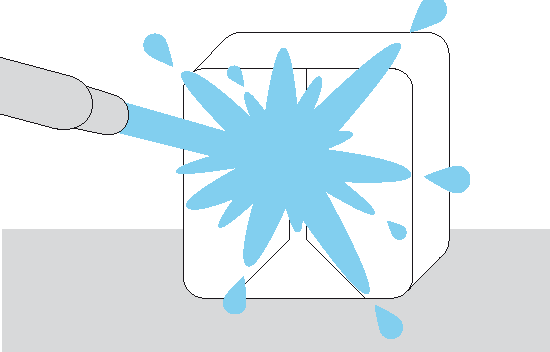

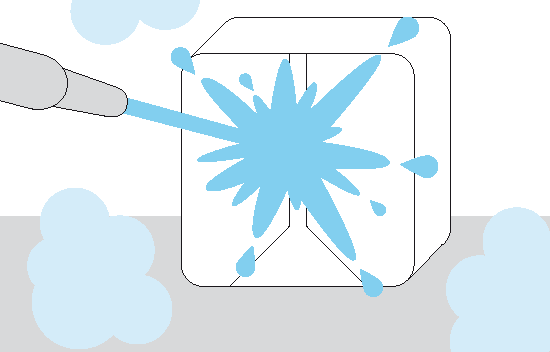

3.6 Protection against rain / snow (precipitation)

The protection rating tests carried out under DIN EN 605.29 are used as comparative tests and for classification of properties. The tests are limited to a few minutes and cannot emulate exposure to rain / snow or cleaning with water jets. In addition, the local conditions may differ so greatly that a general exposure test cannot be defined. The installation regulations for the respective installation situation must be taken into account for this reason.

DIN VDE 0100-520:

5.22.3.1 Cable and conductor systems must be selected and installed such that damage cannot be caused by condensation or ingress of water.

DIN VDE 0100-712: Photovoltaic systems

712.5.22.8.3 External influences that can be anticipated, such as wind, ice formation, temperatures and solar radiation, must be taken into account.

3.7 Protection against retained water (frost)

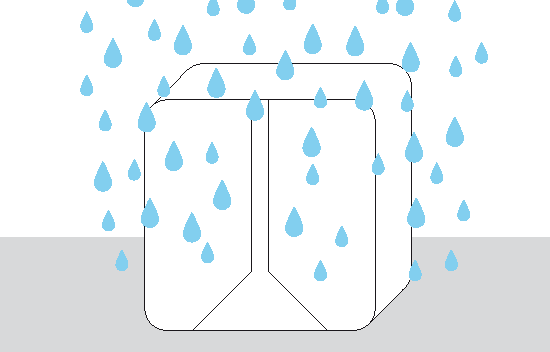

Water frequently collects on surfaces and in recesses in installations that are not protected against precipitation. If this collected water cannot drain off unhindered, it will accumulate. In the event of low temperatures, this water can freeze and cause unpermitted mechanical strains on the housing. This can cause damage to the housing.

DIN VDE 0100-712:

712.522.8.3 External influences that can be anticipated, such as wind, ice formation, temperatures and solar radiation, must be taken into account. It should therefore be ensured during installation that the housing is protected by a roof construction. (See 3.6)

This roof construction may

- already be present in existing structures

- be set up by the user

- be supplied in the form of accessory products from the Spelsberg range.

3.8 Protection against plants and/or mould growth

The plastics used in electrical installation are organic materials. The risk of harm from plants, algae or mould must therefore be considered.

DIN VDE 0100-520:

522.9.1 If experience or empirical evidence shows that plants and / or mould growth can cause damage, the cable and conductor system must be selected accordingly or special protection measures must be provided.

Comment: A laying method that allows corresponding removal of such vegetation must be selected (see Section 529).

Conclusion:

Taking account of the aforementioned parameters, a protected installation is absolutely mandatory for outdoor use and is also described extensively in the installation standards. This is the only way to ensure safe operation of the protective devices.

Supplementary information on outdoor installation – UV-resistance:

The information on the type of protection and UV-resistance is often considered the only characteristics for outdoor installations. However, other factors such as absolute temperature, frequency of temperature change, humidity and chemical influences in particular play an important role with outdoor installations. In addition to impairments through UV-effects, in outdoor installations damage is expected to arise predominantly as a result of chemical influences. So, the outside areas in the vicinity of filling stations, chemical facilities, landfill sites, compressors, sewerage treatment plants etc. should be subjected to particularly critical investigations beforehand.

![[Translate to English - International:] Q4 auf Holz](/media/_processed_/5/e/csm_05c-q4_721bbcf10e.jpg)