On request, we finalise your enclosure with all necessary accessory parts. Not only does this reduce your assembly work, it also eliminates the need to order and stock individual components.

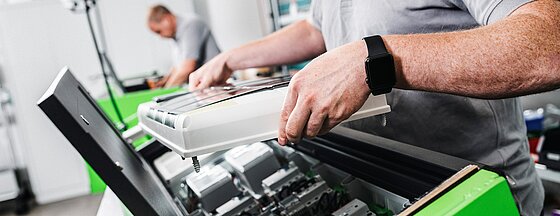

An assembled part is always checked before it leaves our factory. A visual inspection is always carried out and, depending on the application, electrical final tests in the form of measurements to ground, insulation measurements or protective conductor measurements and testing also take place.

We ship the article once everything fits. That way, we can ensure that you receive the accustomed high Spelsberg quality for pre-assembled, partially wired or turnkey enclosures.